что такое collapse piston rings

Content

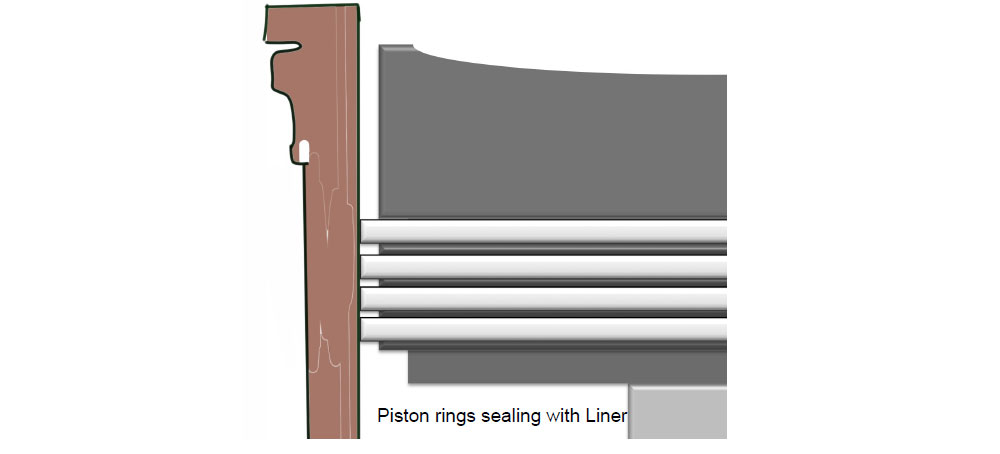

The main function of piston rings inside the combustion chamber is to seal the space and prevent the escape of gases into the lower portion of the engine i.e. under piston area and crankcase.

If the rings are sealing the combustion chamber properly, then it will assist the piston to compress the air fuel mixture efficiently.

Other important functions of piston rings are-

Types

Compression ring or pressure ring:

Scraper or oil control ring:

Types of Piston Ring According to End Joint:

a) Butt (Vertical cut) Joint

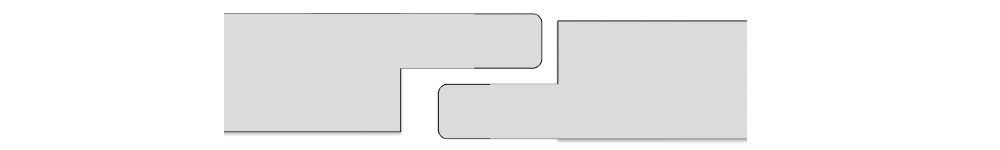

b) Scarfed (Diagonal/Angle cut) Joint

c) Lap / Bayonet Joint

d) Controlled Pressure Relief Ring

Construction of Piston Rings

Grey cast iron piston rings of marine engines are made with the help of pot casting method. In this method, a short cylinder of oval cross section is made and the piston rings are then cut and machined from the cylinder.

With this method, a homogeneous and balanced casting is formed around the entire circumference of the ring.

The piston rings should have tension properties with which the sealing effect is produced. In olden days, the tensile strength was produced by hammering around the circumference of the circular ring. Today, this tension is achieved by two methods:

1. Thermally Tensioned Ring

2. Oval Pot Cam Turning Method

Thermally Tensioned Ring:

The thermally tensioned ring is one of the cheapest methods to induce tension in the piston rings but it is restricted to smaller engines. In this method the piston ring is machined from the circular pot to the required cylinder diameter.

After making the ring, a gap is cut and a metal piece is inserted in the gap, which expands the ring and induces a tension in the ring.

After expanding, the ring and the distance piece is placed inside the oven to relieve any stresses induced during the process. The major disadvantage of this process is that the ring loses its tension because of the heat of the engine.

Oval Pot Cam Turning Method:

The oval pot cam turning method is expensive but the rings produced from this method retain their tension while working in the heat of the engine.

The rings are machined in a cam turning lathe. By changing the cam shape and the oval form, the pressure distribution around the ring is changed and a tension is induced.

After the pot has been machined, a gap of about 7-13% diameter is cut in the ring and rings are grounded on the flanks to ensure good sealing in the piston ring grooves.

The piston rings used in the marine engines should be harder than the liner material in which they are used. To provide additional strength to the piston rings, some materials such as chromium, molybdenum, vanadium, titanium, nickel and copper are added to them.

Chrome plating is one of the most common methods of surface treatment. It is generally used on the running surface of the piston rings and on the landing surfaces i.e. in ring grooves.

Chromium has the advantage of high wear resistance, low friction and corrosion resistance properties. The coating done should be of high quality and be able to operate under all conditions inside the engine without damaging or peeling off or breaking.

It is also one of the methods used for plating the rings. In this method, a gas mixture is passed through an arc generated between the tungsten electrode and water-cooled copper tube.

A very high temperature is thus generated and the gas molecules start to disintegrate. In this plasma state level, carbides and ceramic are sprayed as fine powder, which melts and coats the ring surface.

This plasma coating provides better properties than those provided by the chrome plating.

The disadvantage of chrome and plasma coating is that the thickness of coating and the bonding to parent metal is limited.

A new method of laser hardening treatment is also being used. This produces a wear resistant layer, which is several times thicker than that of the conventional coatings.

Sometimes, copper is plated directly over the chrome layer of the ring. The plating thickness is very thin and the life of this is long enough to cater for running in period. Plasma coated rings are graphite coated to cater with the running-in periods.

Below are the different coatings applied on the piston rings by different manufacturers

| MAN piston ring coatings- |

| CPR ring: Alu. coat 0.1mm, ceramic coat 0.5 mm 2nd ring: Alu. coat 0.1mm 3rd ring: Alu. coat 0.1mm 4th ring: Alu. coat 0.1mm, ceramic coat 0.3mm |

| SULZER piston ring coatings: |

| Top ring: Soft running-in coating-0.1mm 2nd, 3rd, 4th rings: Soft coating 0.1 mm |

Why Piston Rings Brake?

The most common problem in the piston assembly is breaking of piston rings. Following are some main reasons:

Inspection of Piston Rings

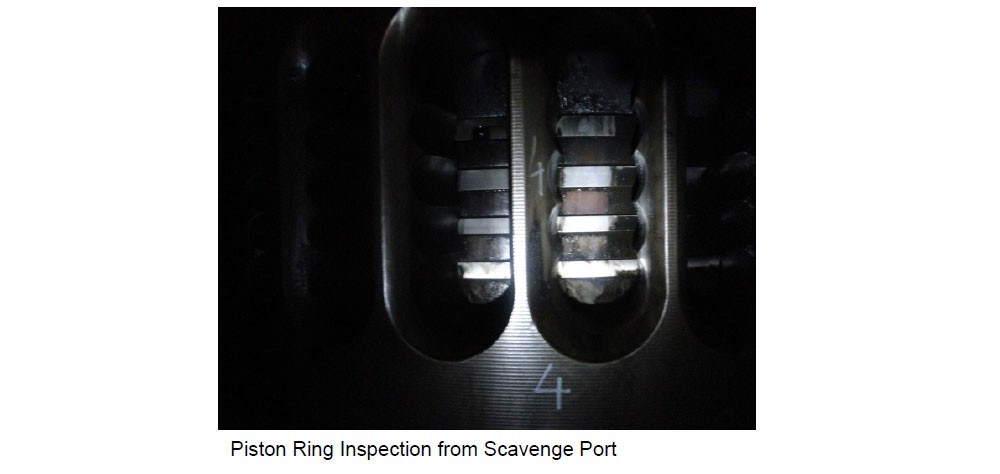

The piston ring can be inspected when the piston is out of the cylinder. When the piston in inside the cylinder, rings can be inspected from inside the scavenge trunk and through the scavenge ports of the liner.

Following things are to be checked in the piston rings:

Sound of ring by tapping it with mallet and hammer- if the sound is damped, it may indicate breakage of the ring

Check butt of the rings for any damage or shear off

Check cracks in the piston ring surface

Check general appearance of the ring

Bright appearance and edge without burrs- indicate good condition

If the brightness has disappeared and edges have burrs- it indicates piston ring seizure

Check scratch marks in the ring surface- It indicates bad fuel quality and blow past

Clearances in Piston Rings

Four important clearances taken in the piston rings are:

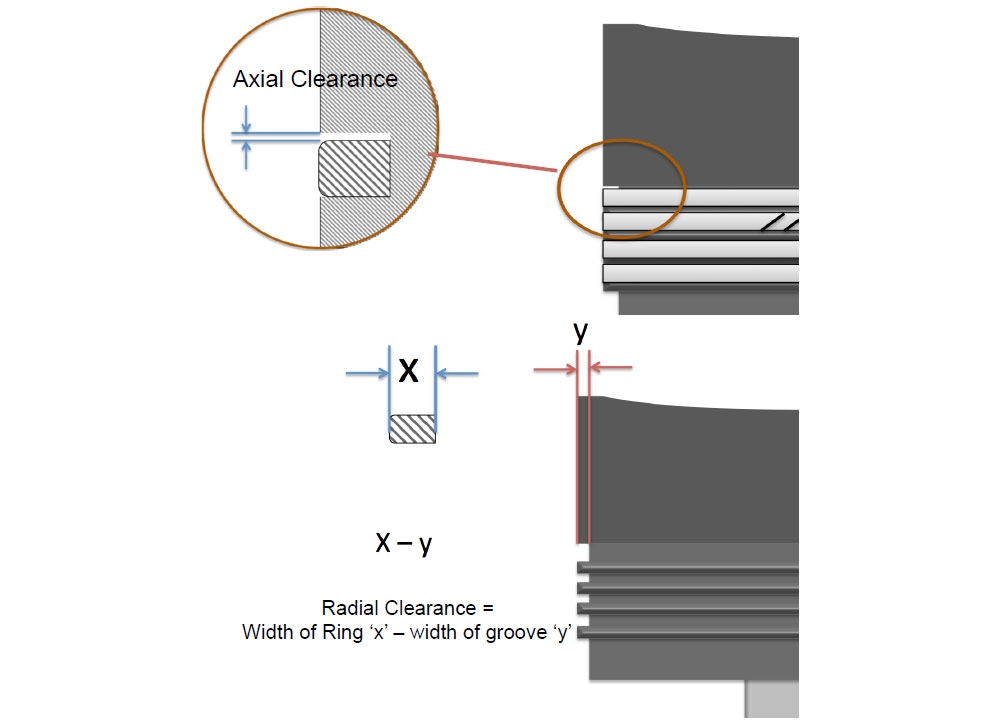

Axial Clearance: It is the clearance between the ring and the groove to be measured at the top part by a feeler gauge. This clearance is to be measured at four different points for each ring.

Radial Clearance: The radial clearance is the difference between the groove depth and ring width, which can be measured by a vernier caliper.

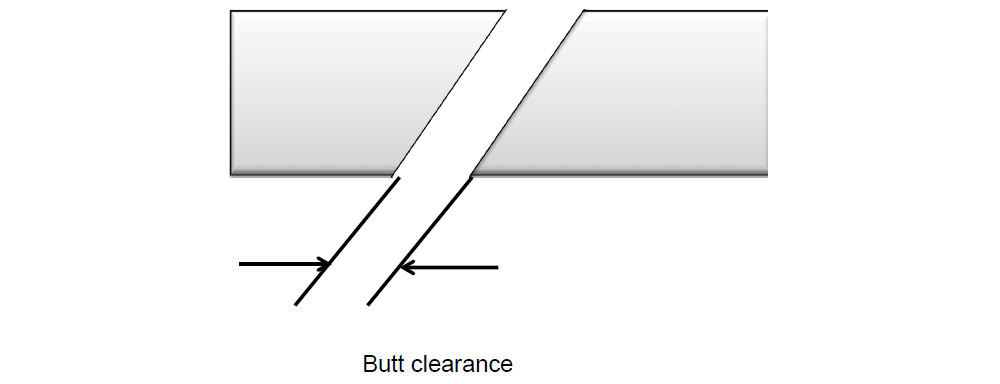

Butt clearance: It is the clearance between the end butt of the ring inside the liner.

The ring is placed inside the liner and the impression can be taken on a paper by applying Prussian blue paste at the butt ends. The gap between the impressions can then be measured.

CPR ring: The controlled pressure relief ring is fitted in the MAN piston as a top ring. The CPR ring has “S” shaped butt joint with six controlled pressure relief grooves milled across the face. Measure the radial depth of the grooves butt clearance at the S joint.

Что такое collapse piston rings

Всем доброго времени суток, кипил ДВС с небольшим жором масла.

Перед установкой хочу поменять кольца и МСК, теперь стает вопрос, какие кольца ставить.

Однозначно буду ставить кольца типа Cr (Наборные) и очень хочется что бы они были стальные.

Искал HASTINGS PISTON RING — 2C4573, но к сожалению их нет в наличии не у кого.

Есть в наличии

NE — 9074800 (На M54B30)

MAHLE — 081RS001010N0 (На M54B30)

Kolbenschmidt — 800050810000 (На N42B20)

Из всего предоставленного хочется Kolbenschmidt но они на ДВС N42 (на сколько помниться цилиндры никасиловые у этого ДВС)

Inspection is an important duty to be carried out on Engines after regular intervals in order to keep the engines in safe working conditions. This series will help you in carrying out the inspection on various marine engine parts.

Piston Ring Material

The piston rings are made of fine-grained alloy cast iron. This material possesses excellent heat and wear-resisting quantities inherent in its graphitic structure.

The elasticity of this material is also enough to impart radial expansion and compression which is required for assembly and removal of the ring, and especially to enable it to exercise flexible pressure on the cylinder walls.

The piston rings are split so that they can be expanded and slipped over the piston head and into the recessed grooves cut in the piston. The rings usually have butt joints, but in some heavy-duty engines, the joint may be angled, lapped, or of the sealed type.

The outer diameter of the ring is somewhat larger than the cylinder bore and the split point is open. When it is installed, it is compressed thus giving it an initial tension, the joint is nearly closed. When in position, it pressed tightly against the cylinder wall.

Ring Coating

To prevent rapid wear, various coatings are used on the compression rings. The coating also affects wear-in. The term wear-in means rapid removal of irregularities of new rings. When new, the rings and cylinder wall have certain irregularities and do not fit perfectly, however, after some time, these irregularities are worn away so that a much better fit is obtained.

Relatively soft substances such as graphite, phosphate and iron oxide, which wear rapidly, are often used to coat the rings and thus help this wear-in. The rate of wear in the cylinder bore can be considerably reduced by chromium-plating the top ring rather than the bore. A chrome-plated ring, however, must not be used in conjunction with a plated bore or hardened linear.

Ring coating also has good oil-absorbing properties. They “soak-up” some oil, thus improving ring lubrication. The coatings also tend to prevent ring scuffing. The scuffing results from metal to metal contact, high local temperatures, and actual small area welding of the ring and cylinder wall metal.

Although the weld breaks by further movement of the piston but scratches are left. The coating prevents such scuffing because a weld cannot take place unless there is actual iron to iron contact.

Установил поршневые кольца

Получил кольца, которые хотел и приступил с постепенной сборке. На самом деле проводил опрос у народа, оказалось, что народный выбор — это TP. Вот они у будут установлены. Но найти их было не совсем просто, два разных магазина принимали мой заказ и привозили мне кольца Rikken вместо TP.

Teikoku Piston Rings, они же TP, они же TPR — код 32376.

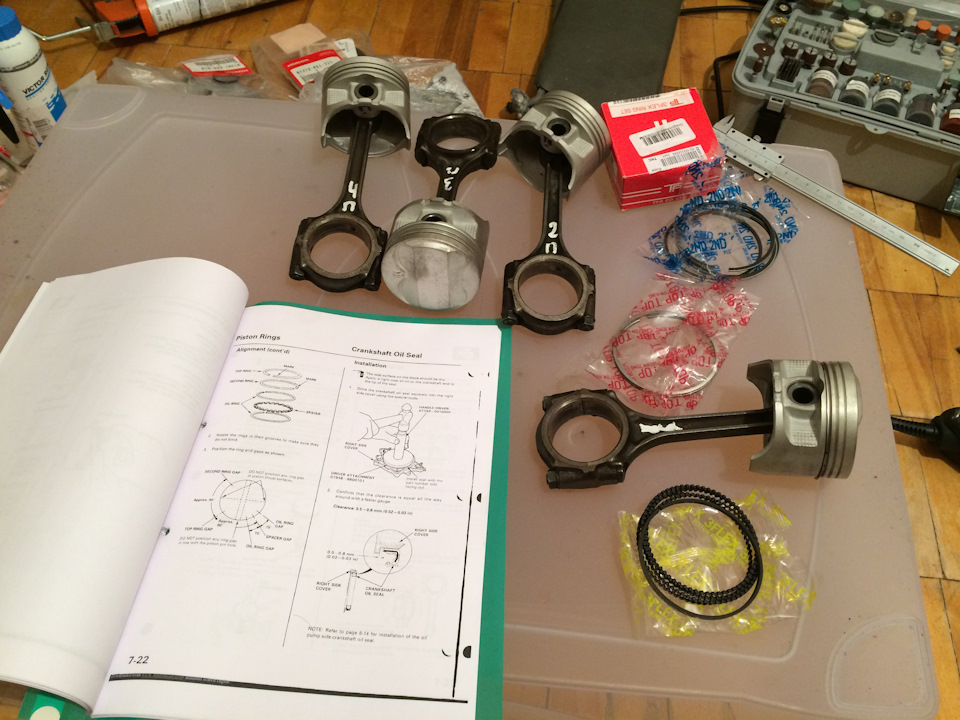

Перед установкой конечно же прочитал мануал и сделал элементарные замеры зазоров

По спецификации зазоры должны быть следующими:

Верхнее кольцо — 0.15 — 0.30 мм

Второе кольцо — 0.30 — 0.45 мм

Маслосъемное кольцо — 0.20 — 0.70 мм

У меня зазоры на первом кольце 0.25 мм, на втором 0.35 мм. Маслосъемные не замерял, но думаю, что тоже в пределах допустимого.

Ну и дело пошло дальше, все по инструкции

Об ориентации маслосъемного спейсера в инструкции ничего не сказано, поэтому направил замок вверх, как было на старых поршнях.

Это уже все 4 поршня готовы

Так же в инструкции ничего не сказано об ориентации самих маслосъемных колец. И на них нет никаких пометок. Скорее всего их можно одевать как угодно. Но я смотрел несколько видеороликов на ютубе (там вазовский мотор собирали) и там было сказано, что направление маслосъемного кольца определяется путем его сдавливания, в результате кольцо постоянно прогибается только в одну сторону. Кто что зает об этом?

Piston Ring Gap [Clearance Measurement]

Piston rings have a gap so that they may be installed into the piston grooves and removed when worn out by expanding them. The gap ensures radial pressure against the cylinder wall thus having an effective seal to prevent leakage of heavy combustion pressure.

Wear in the piston ring grooves makes the rings rise and fall throughout the movement of the piston, so creating a pumping action and resulting in heavy oil consumption. Excessive gas blow-by, loss of compression will also take place if this gap is too much.

During service, the piston ring may have lost some of its elastic properties due to which radial pressure will be reduced on the cylinder wall. This property can be checked by pressing together worn and a new ring, as in figure and observing whether the gap of the worn ring closes more than the new ring.

How to Remove & Fit the Piston rings?

The piston rings should be carefully removed from the piston either with a special removal and installation tool or with three brass strips. The tool expands the ring so that it may be easily removed from the piston. In the latter case, three strips are spaced around the circumference of the piston and the rings are fitted over them.

The strips can be withdrawn and the ring is dropped into the groove. Ring compressor is used to compress the rings for inserting it into the cylinder while assembling the piston and cylinder. The gaps of the rings should not be in line, but they should be staggered so as to prevent the compression from having a direct path to leak by the piston skirt.

Clearances

Ring clearances are necessary to allow movements and thermal expansion. Axial clearance in the groove must be gauged to allow gas pressure to pass to and from the back of the rings. Circumferential clearance at the ring joint is necessary to allow for thermal expansion, but should not allow excessive blow-by of gases.

Required Properties

As well as the above properties the piston rings should have similar thermal expansion to that of the cylinder liner. This is required to maintain their optimum clearances both within their grooves and between them and liner.

Types of Piston Rings: Parts, Function, Material, Clearance [PDF]

In this article, you’ll learn what is piston ring, how it works in a piston? different types of piston rings with their functions, and more.

Also, you can download the PDF version of this article at the end of it.

Types of Piston Rings:

Compression Piston Rings

In modern engines, there are two or three compression rings fitted into the top grooves. The number of compression rings tends to improve the compression ratio. An oil control ring is fitted into the lower groove of the piston. Generally, the second and third compression rings are taper-faced and supplied to improve oil sealing.

Taper-sided compression rings are utilised to control ring-sticking problems in high output engines. It must not be fitted in grooves other than ones of the same section. A special ridge-dodger ring having a small step is specially designed for use in worn engines so that the wear ridge left by the original compression ring is cleared.

In many cases, oil control rings have a series of slots which transfer excess oil through holes in the piston groove to the inside of the piston and so to the sumps but leave sufficient oil to lubricate cylinder walls. Oil control rings slightly more radial pressure than compression rings.

Counter Bored and Scraper Rings

In many engines, these types of piston rings are used for the top and second compression ring. During suction stroke as shown in the figure, the rings twist slightly due to the internal forces produced by cutting away a corner of the rings.

Thus, as the rings move down they rub off the oil that has been left on the cylinder wall by the oil control rings. During the compression stroke when the rings move upward, they tend to skate over the oil film on the cylinder wall. Thus, less oil is sent up into the combustion chamber.

During power stroke as shown in the figure, the combustion pressure causes to untwist the rings, thus they have full-face contact with the cylinder walls for effective sealing. During the exhaust stroke, the same action takes place as in the compression stroke.

Headland Rings

Headland ring is a special type of compression rings, having L-shaped cross-section. It covers or shields the headland area of the piston. This is the area of the piston between the top ring groove and the head of the piston.

This area holds a certain amount of air-fuel mixture that does not burn because the cylinder wall and piston cool this air-fuel mixture below the combustion point. This unburned air-fuel mixture passes out of the engine and can produce smog.

By the use of headland ring on the piston of the special type having chamfered top, this space is eliminated so that the amount of unburned air-fuel mixture exhausted from the cylinder is reduced. This increases horsepower up to 10 %.

The headland ring also has the advantage of good sealing during the power stroke. As combustion starts, the pressure acts quickly on the upper lip of the ring, forcing out thus having good sealing with the cylinder wall.

Why Two Compression Rings?

Usually, two compression rings are installed on the piston. During the power stroke, the pressure increases as high as 70 kgf/cm2 and would be difficult for a single compression ring to hold this much pressure.

If there are two rings, this pressure will be divided between the two rings. The load on the upper ring is reduced so that it does not press quite so hard on the cylinder wall. Wearing of ring and cylinder is also reduced.

Oil Control Rings

Some connecting rods have an oil split hole which splits oils from the oil pan on the cylinder wall during each revolution of the crankpin. For more oil reaches on the cylinder wall that is needed. It must be scraped off and returned to the oil pin. Otherwise, it will go into the combustion chamber and burn.

This would increase oil consumption so that the engine would require the addition of oil at frequent intervals. Also, the burned oil would foul the spark plug, increase the possibility of knocking and hamper the action of compression rings.

Instead of having a cooling, sealing, cleaning, and lubricating effect on the cylinder walls, the oil must be removed from the cylinder wall every time so that it may not enter the combustion chamber. This is done by the oil control ring.

1. One Piece Slotted Cast Iron Type

These types of piston rings have slots between the upper and lower faces that carry on the cylinder wall. The oil scraped off the cylinder wall moves into the slots in the back of the oil ring grooves in a piston and from there it returns to the oil pan.

Some rings of this type are installed with expander rings. The expander spring increases the pressure of the ring on the cylinder wall which improves the oil scraping effect.

2. One Piece Pressed Steel Type

One-piece pressed steel type oil control ring mostly used in an engine with worn cylinder walls. It is made of pressed steel instead of cast iron. It can seal against only one side of the ring groove in the piston at a time, thus leaving an open path through which oil can pass upward toward the combustion chamber.

3. Three Piece Steel Rail Type with an Expander

In three-piece steel rail type oil control ring, the expander spring forces the rails not only upward into contact with cylinder walls but also upward and downward against the upper and lower sides of the ring grooves in the piston. This provides a more effective seal at these three vital points to provide effective oil control.

Why Only One Oil-Control Ring?

Usually, four-piston rings were installed on the long skirt pistons of earlier passenger car engines. The lower two rings were oil-control rings. But the use of lower hood lines reduced the number of rings to three.

Because two compression rings are necessary to withstand the high combustion pressure, hence there remains only one oil control ring. It is possible to use one oil-control ring because of manufacturing improvements and the more effective action of the modern oil-control ring.

Alloying, Machining and Plating

Ship’s two stroke marine diesel engine piston rings are cast from a base metal of pearlitic grey cast iron alloyed with varying percentages of molybdenum, chrome/vanadium, and nickel.

Modern engines use compact graphic cast iron alloyed with the typical elements as described earlier. However, a higher percentage of titanium and vanadium is now used to form hard carbides within the alloy structure.

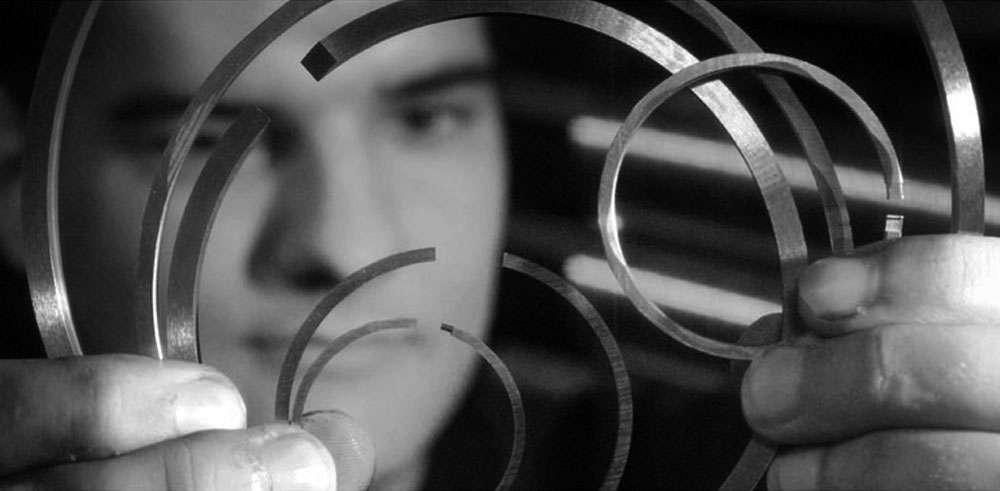

The rings are cast using the “pot casting technique” that produces an oval casting from which the individual rings are machined and parted off, the edges being rounded automatically by the machine.

When I was serving my apprenticeship as a marine fitter in Harland and Wolff Belfast in the 1960’s, I spent a few months in the piston ring section of the engine-works department. Here the rings were machined by a device known as a “hurdy-gurdy” (probable Belfast colloquial term) this machine was right across from my workbench. It resembled a vertical lathe that could accurately machine the inside and outside of the casting; that was clamped in a large circular jawed vice.

Anyway, after machining and parting off the rings from the casting they came across to our benches where we de-burred them, leaving a ⅛“chamfer or round on their outer and inner edges. We then cut through the ring and passed them onto the next section where the gap was measured and very accurately cut to the required size. After this, the rings were trial fitted to the appropriate cylinder sized master gauge before being sent for grinding of the ring landing edges. The last operation was case hardening then the rings were sent to the engine assembly area for fitting to the pistons.

Nowadays the rings are machined using modern equipment; the rings cut, gap set and gagged open before being sent for tensioning and surface grinding of the landings. These surfaces along with the running surfaces are now chrome plated, the running surfaces being coated with a suitable running in compound such as aluminum, graphite or soft copper. A lot different from the old method; but I remember overhauling pistons when I was an engineer at sea, and sometimes there were burrs left on the machined edges of the new rings. These had to be removed before fitting as metal slivers could have broken away and scored the bore. This would never have been allowed in my day; maybe this is why Harland’s B & W engines were so reliable!

Piston Rings

What is Piston ring?

The piston rings are fixed into the grooves of the piston to maintain a good seal between the piston and the cylinder wall.

Piston Rings

In a ship’s main diesel engine the compression piston rings seal the piston against the liner, preventing leakage of the high temperature combustion gases.

Specially machined oil/scraper rings also play their part by removing the excess lubricating oil from the cylinders; helping to prevent an excessive build-up of carbon both around the rings and on the piston crown.

The next few sections examine their fabrication from casting to machining as well as the mechanical properties and design features of the modern engine piston rings; beginning with their required mechanical properties.

Piston Pin

The piston pin connects the piston and the small end of the connecting rod. The piston pin is generally hollow and made from case hardened steel heat treated to produce a hard wear-resistant surface.

2. The pin is attached to the connecting rod with a clamp screw. In this case, the piston bosses form the bearing. A suitable slot is made on the circumference of the piston pin in which the clamp screw is fitted. As shown in the figure.

3. The pin floats in both the piston bosses and the small end of the connecting rod. It is prevented from coming in contact with the cylinder wall by two lock rings fitted in grooves in the outer end of the piston bosses, these rings are called circlips.

This method is now most generally used. In this case, a bushing of phosphor bronze or aluminum is used in the small end of the connecting rod. The bush develops very little wear and renewal only at long intervals.

Piston Pin Fitting

Piston pins may be selectively fitted and, if supplied with the piston, are not interchangeable. In very heavy alternate loading of the piston pins of compression ignition engines, special care is taken to avoid the risk of fatigue cracks.

The external bearing surface is finished to a very high degree of accuracy to ensure the correct fit in the piston and connecting rod. Piston pin should be inspected for wear, cracking, or pitting. circlips should always be renewed, and where soft end pads are fitted, check that they are not loose or cracked.

If you have still any doubts about the “Types of piston rings” you can contact us or ask in the comments.

We have also a Facebook community for you guys. If you like our article then please share it with your friends. Have any questions about any topic just feel free to ask in the comment section.

Finally, subscribe to our newsletter to get notified when we upload new articles.

References

Design Factors and Sealing Requirements.

Inspection Techniques

Piston rings can be easily and regularly examined for scuffing/burn evidence or ring breaks through the scavenge ports. Visual inspection of the size of the chamfer or rounding of the ring edges can also be used as a guide to wear, by comparing this with the size of the rounding on a new ring.

I sailed on a ship which had a Werkspoor 2-stroke main engine that broke piston rings on a regular basis, and I used the above method for inspection of the rings. The bottom part of the cylinder liner was in two halves and contained the scavenge ports. This section was easily split to reveal a full set of rings and the means to replace broken ones. I never did find the reason for the ring breaking, but suspected misalignment between the bottom section and the rest of the liner although these components were doweled, I wonder if they ever found the reason.

Enough of my rambling; a trait of an old Irish retired marine engineer, so back to the present. For a thorough ring inspection to be carried out, it is necessary to remove the piston from the liner, a sketch of this is shown below; please click on the image to enlarge.

Once the piston is on the inspection stool, the ring inspection can be carried out and the following conditions may be evident on the rings.

2. Micro or Macro-Seizures/Scuffing

As the ship’s engineer gains experience it will become second nature to examine the rings and spot any of the above conditions at the regular inspections or on re-assembly after a breakdown.